| Tuning Resources |

Exhaust

Suggestions |

| Engine Swaps | Early Hemis |

Exhaust Suggestions

Listed here are a few suggestions for a solid, high performance exhaust

system.

This article is titled "Testing The Effectiveness Of Performance

Exhaust Components" and was adapted from the July 1995 issue of HOT ROD

Magazine.

Testing the Effectiveness Of Performance

Exhaust Components

Image from Hot Rod Magazine

Of the elements that make up the four-stroke cycle, the exhaust is the last

part of the equation, and it also represents the end of an engine's ability to

make power. Once the exhaust gas leaves the combustion chamber, it's the

exhaust system's job to make sure it gets out fast and stays out. That's why

headers, decent-sized exhaust pipes and good mufflers are necessary on

high-performance vehicles to get the garbage out and make room for more

power. But at what point are headers needed? When are a stock single exhaust

and factory muffler choking the engine, inhibiting horsepower? That's what we

intend to show here.

Of the elements that make up the four-stroke cycle, the exhaust is the last

part of the equation, and it also represents the end of an engine's ability to

make power. Once the exhaust gas leaves the combustion chamber, it's the

exhaust system's job to make sure it gets out fast and stays out. That's why

headers, decent-sized exhaust pipes and good mufflers are necessary on

high-performance vehicles to get the garbage out and make room for more

power. But at what point are headers needed? When are a stock single exhaust

and factory muffler choking the engine, inhibiting horsepower? That's what we

intend to show here.

To test the effectiveness of equipment that allows better exhalation, we

hooked an engine up to Flowmaster's state-of-the-art dyno and tested it with

various exhaust systems. We started with stock, cast-iron manifolds, wimpy

2-inch exhaust pipes and stock mufflers, and ended up with a high performance

system using headers and unrestrictive mufflers. Are there any drawbacks to

these systems? Sure, as with anything that improves performance, there may be

some compromises, and we'll talk about that as well. But in most cases, the

benefits far outweigh the disadvantages.

ENGINE DETAILS

The test engine is about as stock as you can get: a GM Goodwrench 350

replacement motor. Its compression ratio of 7.8:1 and small-valve heads are

not what we'd consider "performance" items, but this will illustrate what

benefits can be realized by using good exhaust components on a stock engine.

The 350 was topped with a cast-iron intake with a functional heat crossover, a

Q-jet carb and an HEI distributor. The only concession to performance was in

the cam, but it's a mild RV grind designed for low-rpm torque. During all

tests, the engine ran on 92-octane gas, and the horsepower and torque were

corrected for 29.92 inches of mercury and 60-degree dry air, which is the

standard correction factor for all legitimate dyno tests. In each case, the

engine was tuned for peak power, which is necessary any time a

performance-enhancing part is added.

TEST 1-STOCK

For a baseline, we wanted a combination representative of a

bone-stock car, as you'd buy it from the elderly couple next door. A set of

stock manifolds with 1 7/8 inch outlets was bolted to the 350, which dumps

into a full-length exhaust system consisting of dual 2-inch pipes and two

stock-type mufflers with 2-inch inlets and outlets. Actually, many cars came

stock with both manifolds connected to a single exhaust pipe and muffler,

which probably would have lowered our baseline power numbers, but for testing

purposes we thought a stock dual exhaust would be more representative. The

engine peaked at 240 horsepower at 4500 rpm and 331 lbs-ft of torque at

3250.

TEST2-FLOWMASTER MUFFLERS

The easiest modification to make to the exhaust system is to add performance

mufflers, so for test two we replaced the stock muffs with a pair of 2-inch

Flowmaster Pressure Buster mufflers. Besides sounding healthier, the mufflers

alone were worth eight horsepower, to 248, and moved the power peak up 250 rpm

to 4750. Torque increased only two lbs-ft at the peak, but the mufflers were

worth up to 10 lbs-ft at higher rpm (see chart).

TEST 3-HEDMAN HEDDERS

After mufflers, the next most popular upgrade is a set of headers. For more

in-depth information on how header design, pipe diameter and length affect

horsepower, check out "How It Works" in the March '95 issue of HOT ROD.

For our stocker dyno mule, we bolted on a set of Hedman Hedders with 1 5/8

inch primaries, and backed them up with a bigger, 2½-inch dual exhaust with

2½-inch Pressure Busters. Why didn't we try the headers with the 2-inch

exhaust? Because when going to headers, you'll have to change at least the

first half of the exhaust system to make them fit, so you might as well get

bigger pipes while you're spending the money.

These changes netted a difference you can actually feel when you floor

the pedal. Power increased across the board, with an increase of 14 horsepower

at the peak. Torque also improved by 21 lbs-ft, from 333 to 354. But more

importantly, the headers lowered the peak torque rpm by 25 So much for the

belief that headers only help at higher rpm.

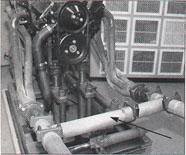

TEST 4-H-PIPE

Image from Hot Rod Magazine

An H-pipe, also known as a crossover pipe, connects both sides of a dual

exhaust. Theoretically, this equalizes the pressure in the pipe which helps

them scavenge the cylinders more efficiently. It also helps get rid of some of

the annoying resonance and frequencies that can occur in dual-exhaust system.

Kevin McClelland at Flowmaster believes that the crossover pipe should be as

close to the engine as possible, and of the same diameter as the rest of the

exhaust, we installed the 2½-inch crossover just after of the header

collectors. Interestingly, this modification picked up horsepower and torque

throughout the powerband, but lost a few lbs-ft the torque peak. It also

raised the torque peak 250 rpm. While this test might not seem conclusive, in

our experience a crossover pipe is worth it if for no other reason than the

decreased resonance or drumming that reaches the inside of the car.

An H-pipe, also known as a crossover pipe, connects both sides of a dual

exhaust. Theoretically, this equalizes the pressure in the pipe which helps

them scavenge the cylinders more efficiently. It also helps get rid of some of

the annoying resonance and frequencies that can occur in dual-exhaust system.

Kevin McClelland at Flowmaster believes that the crossover pipe should be as

close to the engine as possible, and of the same diameter as the rest of the

exhaust, we installed the 2½-inch crossover just after of the header

collectors. Interestingly, this modification picked up horsepower and torque

throughout the powerband, but lost a few lbs-ft the torque peak. It also

raised the torque peak 250 rpm. While this test might not seem conclusive, in

our experience a crossover pipe is worth it if for no other reason than the

decreased resonance or drumming that reaches the inside of the car.

TEST 5-OPEN HEADERS

Drag racers always run with open headers, so that must mean that even a good

exhaust system still costs power, right? Not necessarily. True, with engines

that spin past 7000 rpm and make over 500 horsepower, an inadequate exhaust

might pose a restriction. But even a healthy engine (400 horse-power or so)

can benefit from a good exhaust system, and so can the stocker we flogged on

the dyno. Horsepower and torque were hurt by opening up the headers, and the

peak horsepower even dropped by one. And remember, that's after tuning for the

change.

CONCLUSIONS

| Table of Dyno Figures |

|---|

| Test 1 |

Test 2 |

Test 3 |

Test 4 |

Test 5 |

|---|

| RPM |

LBS-FT | HP |

LBS-FT | HP |

LBS-FT | HP |

LBS-FT | HP |

LBS-FT | HP |

| 2750 |

326 |

171 |

329 |

172 |

353 |

185 |

349 |

182 |

352 |

184 |

| 3000 |

330 |

188 |

333 |

190 |

354 |

202 |

351 |

201 |

352 |

201 |

| 3250 |

331 |

205 |

333 |

206 |

352 |

218 |

352 |

218 |

352 |

218 |

| 3500 |

327 |

218 |

331 |

221 |

350 |

233 |

352 |

234 |

351 |

234 |

| 3750 |

321 |

229 |

325 |

232 |

342 |

244 |

343 |

245 |

340 |

243 |

| 4000 |

310 |

236 |

319 |

243 |

332 |

253 |

336 |

256 |

331 |

252 |

| 4250 |

293 |

237 |

304 |

246 |

316 |

256 |

320 |

259 |

323 |

262 |

| 4500 |

280 |

240 |

288 |

246 |

305 |

262 |

308 |

264 |

307 |

263 |

| 4750 |

265 |

240 |

274 |

248 |

292 |

264 |

292 |

264 |

290 |

263 |

|

Note: Only pertinent table values are shown. |

|---|

The engine we tested is pretty stock, yet it still saw a 10-percent horsepower

gain from headers and performance mufflers. An increase of 24 hp and 22

lbs-ft of torque might not seem so extreme compared to what's available with

nitrous oxide, but it's very good for a relatively inexpensive bolt-on. Also,

the power gains would have been more dramatic with a higher-performance

engine. More compression, cam timing and carburetion make the exhaust side

even more important; stuff more air in the motor and it has a harder time

getting out. HR

More information from the article...

Problems That Are Bound To Pop Up

Hot rodding is a world of compromise. Almost without exception, anything that

makes more power must sacrifice something, be it power at a different rpm,

reliability, noise or whatever. A good exhaust is no different. While power

usually only increases, the hassle factor often does the same. The following

are some of the things you should be ready for when bolting on a set of

headers and a trick exhaust.

- Spark Plug Access - Headers often make it tougher to get to the

spark plugs. Expect plug changes to take about twice the usual length of

time, if not more. ACCEL has recently introduced a spark plug designed just

for headers that is about ½ inch shorter than other plugs, to more easily

clear the tubes.

- Fit - Even the most expensive headers sometimes need massaging

with a hammer to fit around steering boxes or scattershields.

- Noise - Tube headers are thinner than iron manifolds, so they’re

going to be noisier and hotter.

- Leaks - Headers are notorious for leaking, at both the head flange

and the collector. A tip is to use Permatex Ultra Copper silicone on both

surfaces, and Loctite on the bolts. Stage 8 fasteners also ensure a good

seal, and will fit all but the biggest tube headers. The more expensive

headers usually have thicker flanges and tubing, which helps sealing

greatly.

- Plug Wire Burning - Headers can also wreak havoc with plug wires.

The solutions range from proper routing strategy to using insulated wires or

insulating covers.

- Accessory Brackets - Because some accessories, particularly the

alternator, A/C compressor, and smog pump, have at least one bolt connected to

the head, headers will often require adapters to make this stuff fit.

- Starter Access - There’s a good possibility that once the headers

are installed, you won’t be able to get the starter on or off, especially on a

small block Ch%*y. Be prepared.

- Legality - Most of the major header manufacturers have Executive

Order (E.O.) numbers on their headers, but if smog legality is a concern in

your area, you’d better make sure.

Headers

Image from Mopar Action Magazine

Currently, Mopar Performance and Hedman Hedders make headers for '61-'71

Dodge Trucks. Both companies make headers for small block LA-engine

powered trucks while Hedman makes big block headers. For slant-six or

wideblock 318 engines, you will have to do some searching or special

fabricating.

Image from Mopar Action Magazine

Currently, Mopar Performance and Hedman Hedders make headers for '61-'71

Dodge Trucks. Both companies make headers for small block LA-engine

powered trucks while Hedman makes big block headers. For slant-six or

wideblock 318 engines, you will have to do some searching or special

fabricating.

Part Numbers

- '61-'71 Truck Small Block 273-360 Hedman Hedders - # 79010

- '61-'71 Truck Small Block 273-360 Mopar Performance Headers - #

P4529438

- '64-'70 A-100 Van\Truck Small Block 273-360 Hedman Hedders - #79030

- '61-'71 Truck Big Block 383-440 Hedman Hedders - # 79250**

- `72-`91 Truck Small Block 318-360 Hedman Hedders - # 79080 2WD and #

79170 4WD

- `72-`91 Truck Small Block 318-360 Mopar Performance Headers - #P4529439 2WD

and #P4529440 4WD

- `72-`91 Dodge B-series Vans (probably fit`70-`71 as well, but no guarantee

here) - #P4529467

**NOTE: A number of visitors to this site have noted that the Hedman Hedders #79250 do not fit

4x4 trucks. This part number has a problem with interference at the transmission crossmember.

The problem is applicable to `61-mid `68 trucks with the hydraulic clutch setup. The hedders

will fit mid `68-later trucks with the linkage actuated clutch or automatic. To make these fit

`61-`67 4x4 trucks, they must be modified. Also, Jim Patterson wrote in and suggested the use

of Doug Thorley's Tri-Y Headers on mid `68-`71 Trucks, P/N Y-124. Although their true

application is listed to fit `74-`76 trucks, the block and bellhousing setup is the same

dimensionally so they fit well on the older rigs.

{Most} Hedman Hedders are well fitted to the '61-'71 Trucks. The hardest part to

installing the headers is removing the old exhaust since parts are usually

rusted onto the vehicle. Once installed, the next step is finding a

reputable shop to weld the pipes up to the headers and out the back or

side of the truck.

POLYSPHERE ENGINE HEADERS

Headers are available from the aftermarket as an assembly, and two companies

make the flanges and sell kits that allow one to fabricate a set. These

companies are Stans Headers in Seattle and Headers by Ed in Minneapolis. More

information:

For a complete set of headers for your Polysphere engine in a `61-`71 Dodge

Truck, call Harold Johnson of Spitfire Headers in Arkansas at (501) 474-0120.

Special thanks to Bill Pate for this tidbit of information (Bill says the

Headers are a great fit).

Stan's Headers

4715 Auburn Way North

Auburn, WA 98002

(206) 854-5310 or (206) 850-1835

http://www.stans-headers.com/

Headers by ED

P.O. Box 7494

Minneapolis, MN 55407

(612) 729-2802

BLOCK HUGGER HEADERS

Sanderson Street Rod Headers lists in their 1997 Catalog (Chrysler from 318 to

Hemi) Small and Big block headers to fit vehicles that do not have a crossmember

"directly under the center of the motor or a steering box that is within 3" of

the motor."

Sanderson part number DD1 is recommended for 318-360 small block motors. Part

number DD2 (383-440) has a tube size of 1 7/8" and a collector size of 3",

according to their catalog. These are the "Block Hugger" type headers. Both

sizes of these headers are available in plain steel, Jet Hot coated or polished

stainless.

Sanderson Street Rod Headers

517 Railroad Ave.

South San Francisco, CA 94080

Phone: (415) 583-6617

FAX: (415) 583-8475

Special thanks to Julian Dubuc for the info on Sanderson Big Block Hedders.

Tips for Headers in ‘61-’71 Dodge

Trucks.

Use a starter heat shield. These headers are somewhat close to the

starter and solenoid on the driver’s side. To avoid premature failure of the

solonoid or starter, remove it before installing the headers and wrap it with

a thick layer of one-sided aluminum, blanket like insulation. Use aluminum

tape to double wrap all areas of the cover and make sure that all edges are

covered. Also be sure to cover the solenoid, but trim the shield away from the

electrical connections on the solonoid. Finally, use large cable ties to

fasten the shield to the starter. Some aftermarket companies make shields for

Chrysler engines, but these sheetmetal shields do not cover all areas as well

as a homemade shield will.

Use Ultra Copper Silicone Sealant. Hot Rod Magazine

recommended this in the above article, and the author has never encountered

any leaks with the use of this suggestion. Loctite/Permatex makes the

product, and it is available at NAPA auto parts as well as most other

parts stores. Use this product to accompany the header gaskets or factory

exhaust manifold gaskets, not in place of them. The product holds to

extreme tempatures, and cleans up easily when removal is desired.

Plan your entire exhaust system. With careful planning and some

research, one can achieve maximum horsepower gains with a high quality

sound out of the pipes. Here are some suggestions...

- Small-Block engines do best with 2" to 2.5" pipes behind the headers.

- Big-Block Engines output best with at least 2.5" to 3.5" pipes.

- Glass-packs are generally louder than turbo type mufflers. While

glass-packs sometimes give a better sound, at higher engine speeds the

sound can be too loud or otherwise unbearable. Choosing high flow

mufflers can be a little more expensive, but will provide equivalent if

not better horsepower and torque gains when compared with glass-packs.

- Stainless steel pipes are exotic, and darn expensive. If you are

making a mega buck hauler or want something that will last, buy stainless.

Nonetheless, normal steel pipes driven' daily will last an adequate length

of time if not neglected.

- Re-check the bolts every once in a while. Due to the extreme tempatures

and vibration present in an exhaust system, it is important to keep all

fasteners as tight as possible. If neglected, the bolts can loosen and allow

the collector and head flanges to warp which will forever ruin the headers.

Please Note: This page is intended as a guide

and is not guaranteed in any way. All info above is to the best knowledge of

the author.

Of the elements that make up the four-stroke cycle, the exhaust is the last

part of the equation, and it also represents the end of an engine's ability to

make power. Once the exhaust gas leaves the combustion chamber, it's the

exhaust system's job to make sure it gets out fast and stays out. That's why

headers, decent-sized exhaust pipes and good mufflers are necessary on

high-performance vehicles to get the garbage out and make room for more

power. But at what point are headers needed? When are a stock single exhaust

and factory muffler choking the engine, inhibiting horsepower? That's what we

intend to show here.

Of the elements that make up the four-stroke cycle, the exhaust is the last

part of the equation, and it also represents the end of an engine's ability to

make power. Once the exhaust gas leaves the combustion chamber, it's the

exhaust system's job to make sure it gets out fast and stays out. That's why

headers, decent-sized exhaust pipes and good mufflers are necessary on

high-performance vehicles to get the garbage out and make room for more

power. But at what point are headers needed? When are a stock single exhaust

and factory muffler choking the engine, inhibiting horsepower? That's what we

intend to show here. An H-pipe, also known as a crossover pipe, connects both sides of a dual

exhaust. Theoretically, this equalizes the pressure in the pipe which helps

them scavenge the cylinders more efficiently. It also helps get rid of some of

the annoying resonance and frequencies that can occur in dual-exhaust system.

Kevin McClelland at Flowmaster believes that the crossover pipe should be as

close to the engine as possible, and of the same diameter as the rest of the

exhaust, we installed the 2½-inch crossover just after of the header

collectors. Interestingly, this modification picked up horsepower and torque

throughout the powerband, but lost a few lbs-ft the torque peak. It also

raised the torque peak 250 rpm. While this test might not seem conclusive, in

our experience a crossover pipe is worth it if for no other reason than the

decreased resonance or drumming that reaches the inside of the car.

An H-pipe, also known as a crossover pipe, connects both sides of a dual

exhaust. Theoretically, this equalizes the pressure in the pipe which helps

them scavenge the cylinders more efficiently. It also helps get rid of some of

the annoying resonance and frequencies that can occur in dual-exhaust system.

Kevin McClelland at Flowmaster believes that the crossover pipe should be as

close to the engine as possible, and of the same diameter as the rest of the

exhaust, we installed the 2½-inch crossover just after of the header

collectors. Interestingly, this modification picked up horsepower and torque

throughout the powerband, but lost a few lbs-ft the torque peak. It also

raised the torque peak 250 rpm. While this test might not seem conclusive, in

our experience a crossover pipe is worth it if for no other reason than the

decreased resonance or drumming that reaches the inside of the car.